![[Translate to English:] Funktionale Sicherheit: NTSafetySolutions](/fileadmin/_processed_/c/7/csm_Funktionale-Sicherheit-NTSafetySolutions_7cd792febd.png)

Functional Safety

Electronics and software development for functionally safe systems

Whether large-scale plants, machine tools, vehicles or medical equipment - the demand for functionally safe solutions is increasing. (Functional) Safety is a relevant quality feature: It not only prevents hazards and thus reduces liability risks for manufacturers, but also reduces unplanned shutdowns for the user and thus increases availability and productivity.

With NewTec as your partner, you systematically develop products that reliably meet all current functional safety standards - efficiently and at low cost.

Our platform solutions and services for safety engineering cover the complete development cycle of your safe system - from risk assessment and System Safety Requirements Specification (SSRS) to safety plan, system design, hardware and software development, certification and approval.

What is functional safety?

Functional safety is defined in the basic safety standard IEC 61508 as "part of the overall safety, related to the EUC and the EUC control system, which depends on the correct functioning of the E/E/PE safety-related system and other risk-reducing measures". How should this definition be understood?

By "safety", ISO and IEC mean the absence of intolerable risks (ISO/IEC Guide 51:2014). This is based on the conviction that there can be no absolute safety (the absence of any risks). Depending on the type and cause of possible risks, a distinction is made between different types of safety, such as electrical safety, information security, or "functional safety": Functional safety involves protecting people and the environment from hazards caused by malfunctions in technical systems (e.g., the failure of a brake or a railroad signal).

Safety-related systems

Special safety functions usually provide protection against malfunctions in complex technical systems. These monitor the systems or system components with potential danger (EUC: Equipment under Control) during operation and react automatically to potentially dangerous conditions. Examples of "safety-related systems" (SRS) with such safety functions are emergency shutdown systems in plants or machines, the ABS in cars, speed monitoring in turbines or the monitoring of pressure, temperature or filling levels in chemical plants.

Functional safety: legal principles and standards

Manufacturers of technical systems and components are required by law to ensure their safety. They are liable for damage if the product defect that caused it was identifiable according to the "state of science and technology" when it was placed on the market (§ 1 ProdHaftG).

The safety requirements that products must meet are defined by EU directives and national laws. In Germany, these include in particular the Product Safety Act (ProdSG) and legal ordinances for specific product groups, such as the Machinery Ordinance or the Elevator Ordinance. In addition, there are directly applicable EU regulations such as the Medical Devices Regulation (EU) 2017/745.

The technical details and the procedure for developing and operating safe systems are described in standards. The most important safety standard is IEC 61508 on the "functional safety of safety-related electrical/electronic/programmable electronic systems" (E/E/PE systems). It also serves as a generic base standard for application-specific sector standards, e.g. ISO 26262 for the functional safety of road vehicles, EN 60601 for medical technology or EN 62061 for safety-related parts of machine control systems.

Certification and approval

By fully documenting or certifying compliance with relevant standards, manufacturers can provide the legally required proof that the safety of their products corresponds to the "state of the art". Many safety-relevant products also require approval, for which an independent assessment of functional safety (Functional Safety Assessment) is required.

NewTec's safety experts are familiar with all relevant development standards. NewTec supports you in the preparation of the necessary documents, takes care of the examination of the safety concept at the TÜV and accompanies your way to certification or approval.

How is functional safety implemented?

Technical products are becoming increasingly complex. This increases the number of potential sources of error. A structured safety process is therefore crucial to the success of any safety-oriented development. The mentioned standards describe the suitable procedure for this throughout the entire "safety lifecycle" - from product concept and implementation, through market launch and updates, to deactivation and disposal.

For all lifecycle phases, manufacturers must identify the hazards to be assumed (risk and hazard analysis) and reduce them to an acceptable level with appropriate measures (ALARP: as low as reasonably practicable). A structured process helps to anticipate systematic (man-made) errors in the development, use or maintenance of the product, and to identify and control random, unforeseeable errors - especially hardware failures - with the aid of appropriate measures. All processes within the scope of this procedure must be documented by the manufacturer.

The effectiveness or reliability of safety functions (safety integrity) required for an application depends on the hazards associated with the application. A distinction is made between four safety integrity levels (SIL 1 to 4).

"Safety by Design": Safe product development

Errors in safety development can cost a lot of money: through increased development effort due to a non-safety-optimized design, problems with certification and expensive subsequent changes, lost sales due to delayed market introduction and, last but not least, incalculable product liability risks.

With a structured, experience-based approach, NewTec's safety experts help you avoid these risks and reduce the effort required for your functionally safe development. NewTec's proven safety management process complements your existing product development processes with a holistic, structured approach. This enables you to effectively synchronize product development and safety development.

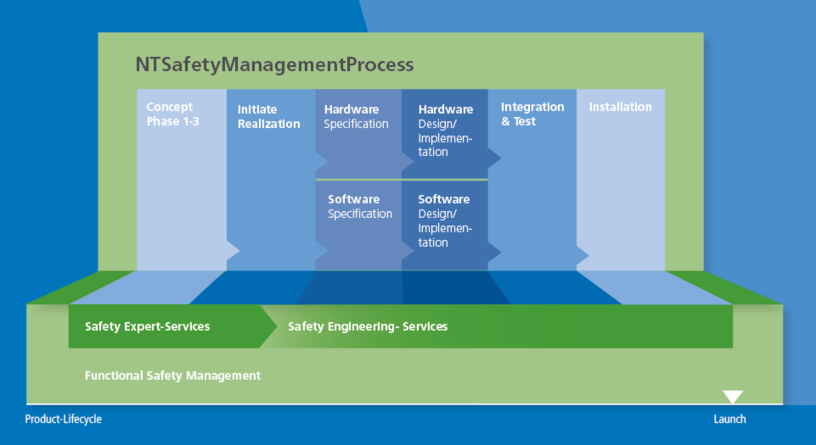

NewTec's management process for functionally safe products

Safety process consulting by NewTec

- Introduction of a structured safety process

- Integration of the safety process into your product development process

- Training of safety process managers

- Safety consulting

- Safety culture

No safety without security

In networked systems, safety today always includes both: functional safety against errors and IT security against attacks and manipulation. Malfunctions can also be triggered by hackers and malware; functional safety measures can endanger security and vice versa.

With synchronized safety and security management processes, NewTec ensures that the requirements from both perspectives are taken into account and harmonized - "Safety & Security by Design". Our approach is based on proven best practices, the requirements of the German Federal Office for Information Security (BSI) and the industrial security standard IEC 62443. We have closely coordinated our security management process with TÜV to facilitate and accelerate certifications.

Engineering services from NewTec: Faster to market

Safety-oriented developments, including approval and integration, can be very time-consuming and expensive, and require specialist know-how. The wide range of expert- and project services from NewTec relieve and speed up your product development.

In addition, we support you in certification, approval and integration and train your employees on safety topics. We are also prepared to help you build up the necessary change management skills to develop your safety culture.

Expert Services

- Analysis of your existing safety process landscape

- Introduction of safety processes and support of their compliance

- Safety concepts, safety plans, V&V plans, safety requirements specifications

- Approval support with concept review at TÜV

- Interim Functional Safety Manager

- Training for process managers in the area of functional safety

- Training for project staff (safety, requirements & systems engineering, safety management).

Find out in detail about our complete training program.

Safety engineering

- Hardware development from specification to series hardware

- Firmware development for FPGA and CPLD for functionally safe systems

- Software development for functionally safe systems

- Requirements engineering in all development phases

- Systems engineering and support through all project phases from kick-off to project completion

Ready-to-copy: functional safe platforms

Accelerate your product development! NewTec's safety development platforms contain ready-to-use hardware and software components for safe product developments - e.g. in the automotive, transportation, industrial and medical technology sectors. This means you don't start from scratch, but have access to basic safety concepts and IP cores based on application-specific platforms with exemplary safety concept approval.

The powerful reference designs for various safety applications are ready to copy and can be easily adapted to your individual requirements. How-to guides and detailed documentation facilitate the implementation of relevant safety standards.

Find out more about our entire platform portfolio.

NTBatteryManagementSystem

NewTec NTBatteryManagementSystem (NTBMS) is an e-mobility reference design and complete safety support package for Battery Management Systems. It is constructed with a two board approach: a functional safety System-on-Module board and a Battery Management System (BMS) application board. Learn more about the NTBatteryManagementSystem.

NTSafeDriveMonitor

The NTSafeDrive safety development platform supports manufacturers of servo drives with the integration of additional safety functions up to SIL 3. A qualified universal safety IP core contains all functions for a safe drive monitoring. NTSafeDrive supports all of the safety functions described in IEC 61800-5-2. Inquire in detail about the NTSafeDriveMonitor.

NTMicroDrive

The holistic NTMicroDrive HVC 4223F software package for the TDK-Micronas embedded controller reduces the workload with the development of safe motion control applications (SIL 2 / ASIL A). It consists of a flexible, parameter-adjustable controller firmware which also monitors electricity consumption, current and temperature zones, as well as a testing tool with a graphic user interface. Get more information on the topic of our NTMicroDrive.